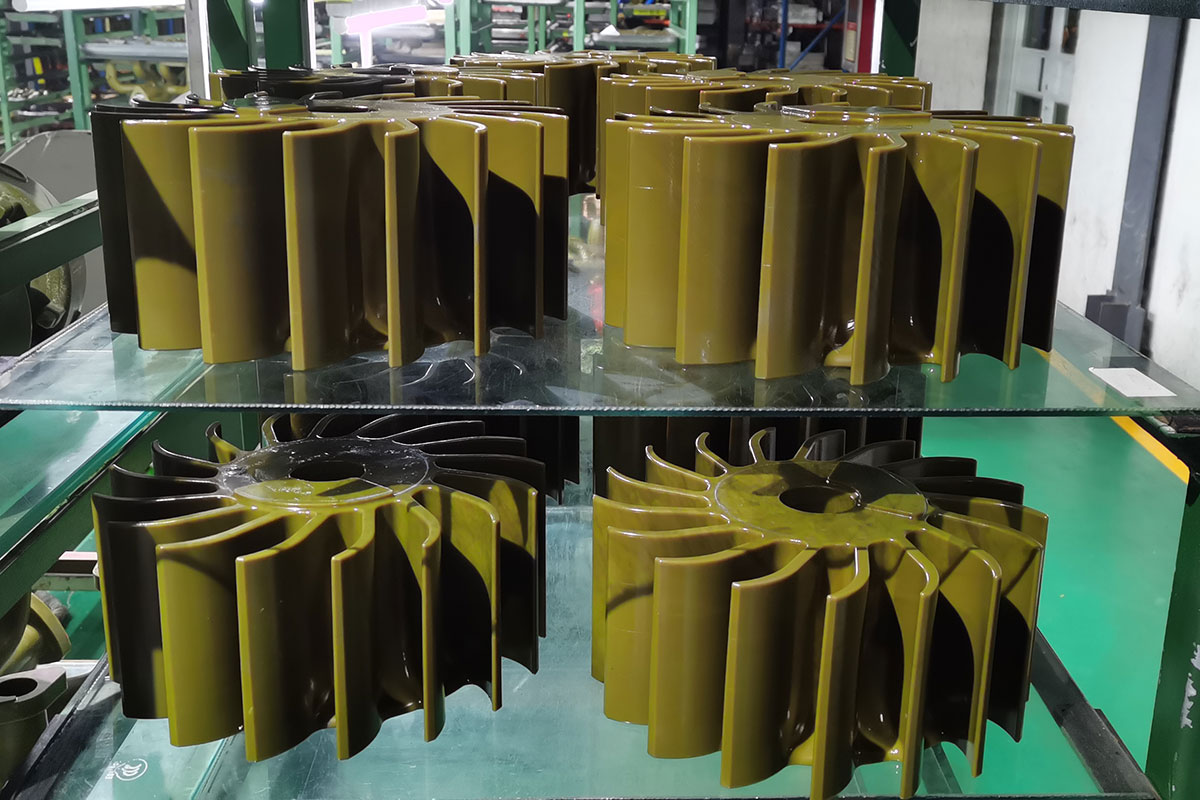

Sìona OEM àbhaisteach stàilinn impeller lepròiseas tilgeadh tasgaidh cèir caillte.

Is e na h-eileamaidean bunaiteach alloy de thasgadh tasgaidh nicil-bonn no stàilinn gun staoin cromium, nicil, agus molybdenum (no “moly”). Bidh na trì co-phàirtean sin a’ dearbhadh structar gràin agus feartan meacanaigeach an tilgeadh agus bidh iad mar mheadhan air comas an tilgeadh sabaid an aghaidh teas, caitheamh agus coirbeachd.

Tha susbaint chromium aig a’ char as lugha de 10.5% aig stàilinn gun staoin, ga fhàgail nas seasmhaiche ri àrainneachdan leaghaidh creimneach agus ri oxidation. Ach, chan eil seo iomlan. Tasgadh stàilinn gun staointha tilgeadh “dìonach bho chreimeadh” nuair a thèid an cleachdadh ann an àrainneachdan leaghaidh agus bhalbhaichean fo 1200 ° F (650 ° C) agus “teas-dhìonach” nuair a thèid an cleachdadh os cionn an teòthachd seo.

Buannachdan co-phàirtean tilgeadh tasgaidh:

- Crìoch uachdar sàr-mhath agus rèidh

- fulangas meud teann.

- Cumaidhean iom-fhillte agus toinnte le sùbailteachd dealbhaidh

- Comas ballachan tana a thilgeil mar sin pàirt tilgeadh nas aotroime

- Taghadh farsaing de mheatailtean tilgeadh agus aloidhean (iarann agus neo-iarannach)

- Chan eil feum air dreach ann an dealbhadh molltair.

- Lùghdaich an fheum air innealachadh àrd-sgoile.

- Ìosal sgudal stuthan.

| Stuthan airsonTasgaidh tasgaidhPròiseas aigFùirneis RMC | |||

| Roinn-seòrsa | Ìre Sìona | Ìre na SA | Ìre na Gearmailt |

| Ferritic stàilinn | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Stàilinn Martensitic | 1Cr13, 2Cr13,3Cr13,4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Stàilinn Austenitic stainless | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404, 9. 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Sileadh cruadhachadh stàilinn gun staoin | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex stàilinn gun staoin | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| Stàilinn Àrd Mn | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Stàilinn inneal | Chr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Stàilinn a tha an aghaidh teas | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Alloy Nickle-bonn | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX (66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Aluminium Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Alloy copair | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800,C52100,C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Alloy cobalt-base | UMC50, 670, Ìre 31 | 2. 4778 | |

| LUCHD-OBRACHAIDH TAISGAIDH | |||

| òirlich | Millimeters | ||

| Tomhas | Fulangas | Tomhas | Fulangas |

| Suas gu 0.500 | ±.004" | Suas gu 12.0 | ± 0.10mm |

| 0.500 Gu 1.000” | ±.006" | Bho 12.0 gu 25.0 | ± 0.15mm |

| Bho 1.000 gu 1.500 ” | ±.008" | bho 25.0 gu 37.0 | ± 0.20mm |

| 1.500 Gu 2.000” | ±.010" | Bho 37.0 gu 50.0 | ± 0.25mm |

| Bho 2.000 gu 2.500 ” | ±.012" | Bho 50.0 gu 62.0 | ± 0.30mm |

| Bho 2.500 Gu 3.500 ” | ±.014" | Bho 62.0 gu 87.0 | ± 0.35mm |

| Bho 3.500 gu 5.000 ” | ±.017" | Bho 87.0 Gu 125.0 | ± 0.40mm |

| Bho 5.000 gu 7.500 ” | ±.020" | Bho 125.0 gu 190.0 | ± 0.50mm |

| Bho 7.500 gu 10.000 ” | ±.022" | Bho 190.0 gu 250.0 | ± 0.57mm |

| Bho 10.000 gu 12.500 " | ±.025" | Bho 250.0 gu 312.0 | ± 0.60mm |

| Bho 12.500 gu 15.000 | ±.028" | Bho 312.0 Gu 375.0 | ± 0.70mm |