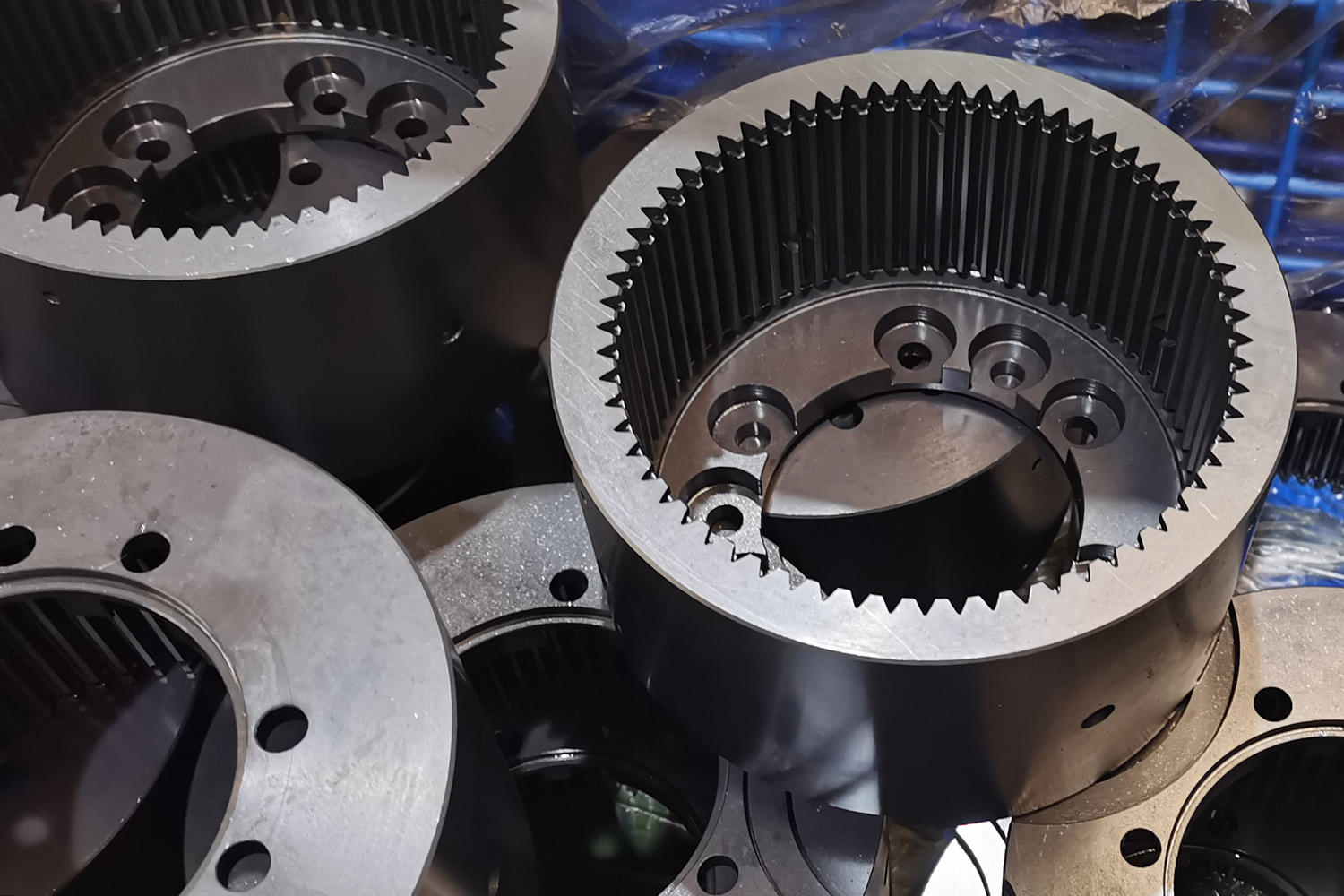

Sìona OEM àbhaisteach alloy stàilinn tilgeadh lepròiseas tilgeadh tasgaidh cèir caillte. Bithear a’ cleachdadh stàilinn gualain, stàilinn alloy ìosal, agus tilgeadh stàilinn inneal ann an grunniarrtasan tionnsgalachagusgèaraichean gnàthaichte. Leis na h-ìrean iomadach aca, faodar stàilinn agus an alloys a làimhseachadh le teas gus an toradh agus an neart tensile a leasachadh; agus, atharraich cruas no ductility a rèir feumalachdan tagraidh an innleadair no na feartan meacanaigeach a tha thu ag iarraidh.

Is e tilgeadh tasgaidh stàilinn alloy a tha an aghaidh caitheamh na pàirtean tilgeadh a chaidh a thoirt a-mach le pròiseas tilgeadh tasgadh cèir caillte air a dhèanamh de stàilinn alloy a tha an aghaidh caitheamh. Aig RMC Foundry, is e na prìomh phròiseasan tilgeadh gainmhich a dh’ fhaodadh sinn a chleachdadh airson stàilinn alloy a tha an aghaidh caitheamh, tilgeadh gainmhich uaine, tilgeadh gainmhich còmhdaichte le roisinn, tilgeadh molltair gainmhich gun bhèicearachd, tilgeadh foam caillte, tilgeadh falamh agus tilgeadh tasgaidh. Tha an làimhseachadh teas, làimhseachadh uachdar agus innealachadh CNC cuideachd rim faighinn aig an fhactaraidh againn a rèir do dhealbhan agus riatanasan.

Am measg measgachadh farsaing de aloidhean tilgeadh, tha stàilinn tilgeadh caitheamh-dhìonach na stàilinn alloy air a chleachdadh gu farsaing. Bidh stàilinn tilgeadh caitheamh-dhìonach gu ìre mhòr a’ leasachadh an aghaidh caitheamh tilgeadh stàilinn le bhith a’ cur susbaint eadar-dhealaichte de eileamaidean alloying, leithid manganese, chromium, carbon, msaa, ris an alloy. Aig an aon àm, tha an aghaidh caitheamh de thilgeadh stàilinn caitheamh-dhìonach cuideachd an urra ris an dòigh làimhseachaidh teas a bhios an fhùirneis a’ cleachdadh agus structar an tilgeadh.

A rèir feartan caitheamh eadar-dhealaichte, faodar caitheamh tilgeadh stàilinn a roinn ann an caitheamh sgrìobach, caitheamh adhesive, caitheamh sgìths, caitheamh corrach agus caitheamh fretting. Bidh tilgeadh stàilinn caitheamh-dhìonach air a chleachdadh sa mhòr-chuid ann an raointean gnìomhachais le suidheachaidhean obrach iom-fhillte agus riatanasan coileanaidh meacanaigeach àrd, leithid mèinnearachd, Meatailteachd, togail, cumhachd, peitriceimiceach, glèidhteachas uisge, àiteachas agus gnìomhachasan còmhdhail. Bidh tilgeadh stàilinn a tha an aghaidh caitheamh air a chleachdadh sa mhòr-chuid ann an suidheachaidhean sgrìobadh le luchd buaidh sònraichte, leithid uidheamachd bleith, cladhairean, pronnadh, tractaran, msaa.

| Ìre Co-ionann de Cast Alloy Steel bho dhiofar mhargaidhean | |||||||||

| CRUTHAICHEAN | AISI | W-stuff | DIN | BS | SS | AFNOR | UNE/IHA | JIS | UNI |

| Stàilinn Alloy Ìosal | 9255 | 1.0904 | 55 Si 7 | 250 A 53 | 2090 | 55 S 7 | 56 Si7 | - | 5 SSi8 |

| 1335 | 1. 1167 | 36 Mn 5 | 150 M 36 | 2120 | 40M 5 | 36Mn5 | SMn 438(H) | - | |

| 1330 | 1.1170 | 28 Mn 6 | 150 M 28 | - | 20m 5 | - | SCMn1 | C28MN | |

| P4 | 1.2341 | X6 CrMo 4 | - | - | - | - | - | - | |

| 52100 | 1.3505 | 100 Chr 6 | 534 A 99 | 2258 | 100 C6 | F.131 | SUJ 2 | 100Cr6 | |

| A204A | 1.5415 | 15 Mo 3 | 1501 240 | 2912 | 15 d 3 | 16 Mo3 | STBA 12 | 16Mo3 KW | |

| 8620 | 1.6523 | 21 NiCrMo 2 | 805 M 20 | 2506 | 20 NCD 2 | F.1522 | SNCM 220(H) | 20NiCrMo2 | |

| 8740 | 1.6546 | 40NiCrMo22 | 311 - Seòrsa 7 | - | 40 NCD 2 | F.129 | SNCM 240 | 40NiCrMo2(KB) | |

| - | 1.6587 | 17CrNiMo6 | 820 A 16 | - | 18 NCD 6 | 14 NiCrMo13 | - | - | |

| 5132 | 1.7033 | 34 Chr 4 | 530 A 32 | - | 32 C 4 | 35Cr4 | SCr430(H) | 34Cr4(KB) | |

| 5140 | 1.7035 | 41 Chr 4 | 530 A 40 | - | 42 C 2 | 42 Chr 4 | SCr 440 (H) | 40Cr4 | |

| 5140 | 1.7035 | 41 Chr 4 | 530 A 40 | - | 42 C 2 | 42 Chr 4 | SCr 440 (H) | 41Cr4 KB | |

| 5140 | 1.7045 | 42 Chr 4 | 530 A 40 | 2245 | 42 C 4 TS | F.1207 | SCr 440 | - | |

| 5115 | 1.7131 | 16 MnCr 5 | (527 M 20) | 2511 | 16 MC 5 | F.1516 | - | 16MnCr5 | |

| 5155 | 1.7176 | 55 Chr 3 | 527 A 60 | 2253 | 55 C3 | - | SUP 9(A) | 55Cr3 | |

| 4130 | 1.7218 | 25 CrMo 4 | 1717CDS 110 | 2225 | 25 CD 4 | F.1251/55Cr3 | SCM 420 / SCM430 | 25CrMo4(KB) | |

| 4135 (4137) | 1.7220 | 35 CrMo 4 | 708 A 37 | 2234 | 35 CD 4 | 34 CrMo 4 | SCM 432 | 34CrMo4KB | |

| 4142 | 1.7223 | 41 CrMo 4 | 708 M 40 | 2244 | 42 CD 4 TS | 42 CrMo 4 | SCM 440 | 41 CrMo 4 | |

| 4140 | 1.7225 | 42 CrMo 4 | 708 M 40 | 2244 | 40 CD 4 | F.1252 | SCM 440 | 40CrMo4 | |

| 4137 | 1.7225 | 42 CrMo 4 | 708 M 40 | 2244 | 42 CD 4 | F.1252 | SCM 440 | 42CrMo4 | |

| A387 12-2 | 1.7337 | 16 CrMo 4 4 | 1501 620 | 2216 | 15 CD 4.5 | - | - | 12CrMo910 | |

| - | 1.7361 | 32CrMo12 | 722 M 24 | 2240 | 30 CD 12 | F.124.A | - | 30CrMo12 | |

| A182 F-22 | 1.7380 | 10 CrMo9 10 | 1501 622 | 2218 | 12 CD 9, 10 | F.155 / TU.H | - | 12CrMo9 10 | |

| 6150 | 1.8159 | 50 CRV 4 | 735 A 50 | 2230 | 50 CV 4 | F.143 | SUP 10 | 50CrV4 | |

| - | 1.8515 | 31 CrMo 12 | 722 M 24 | 2240 | 30 CD 12 | F.1712 | - | 30CrMo12 | |

| - | - | - | - | - | - | - | - | - | |

| Stàilinn alloy meadhanach | W1 | 1.1545 | C105W1 | BW1A | 1880 | Y 105 | F.5118 | SG 3 | C100 KU |

| L3 | 1.2067 | 100Cr6 | BL 3 | (2140) | Y 100 C6 | F.520 L | - | - | |

| L2 | 1.2210 | 115 CRV 3 | - | - | - | - | - | - | |

| P20 + S | 1.2312 | 40 CrMnMoS 8 6 | - | - | 40 CMD 8 +S | X210CrW12 | - | - | |

| - | 1.2419 | 105WCr6 | - | 2140 | 105W C 13 | F.5233 | SKS 31 | 107WCr5KU | |

| O1 | 1.2510 | 100 MnCrW 4 | BO1 | - | 90MnWCrV5 | F.5220 | (SK53) | 95MnWCr5KU | |

| S1 | 1.2542 | 45 WCrV 7 | BS1 | 2710 | 55W20 | F.5241 | - | 45WCrV8KU | |

| 4340 | 1.6582 | 34 CrNiMo 6 | 817 M 40 | 2541 | 35 NCD 6 | F.1280 | SNCM 447 | 35NiCrMo6KB | |

| 5120 | 1.7147 | 20 MnCr 5 | - | - | 20 MC 5 | - | - | - | |

| - | - | - | - | - | - | - | - | - | |

| Inneal agus Àrd Alloy Steel | D3 | 1.2080 | X210 Cr 12 | BD3 | 2710 | Z200 C 12 | F.5212 | SKD 1 | X210Cr13KU |

| P20 | 1.2311 | 40 CrMnMo 7 | - | - | 40 CMD 8 | F.5263 | - | - | |

| H13 | 1.2344 | X40CrMoV 5 1 | BH13 | 2242 | Z 40 CDV 5 | F.5318 | SKD 61 | X40CrMoV511KU | |

| A2 | 1.2363 | X100 CrMoV 5 1 | BA2 | 2260 | Z 100 CDV 5 | F.5227 | SKD 12 | X100CrMoV51KU | |

| D2 | 1.2379 | X155 CrMoV 12 1 | BD2 | 2310 | Z 160 CDV 12 | F.520.A | SKD11 | X155CrVMo121KU | |

| D4 (D6) | 1.2436 | X210 CrW 12 | BD6 | 2312 | Z 200 CD 12 | F.5213 | SKD 2 | X215CrW121KU | |

| H21 | 1.2581 | X30WCrV9 3 | BH21 | - | Z 30 WCV 9 | F.526 | SKD5 | X30WCrV 9 3 KU | |

| L6 | 1.2713 | 55NiCrMoV 6 | - | - | 55 NCDV 7 | F.520.S | SKT4 | - | |

| M 35 | 1.3243 | S6/5/2/5 | BM 35 | 2723 | 6-5-2-5 | F.5613 | SKH 55 | HS6-5-5 | |

| M 2 | 1.3343 | S6/5/2 | BM2 | 2722 | Z 85 WDCV | F.5603 | SKH 51 | HS6-5-2-2 | |

| M 7 | 1.3348 | S2/9/2 | - | 2782 | 2 9 2 | - | - | HS2-9-2 | |

| HW 3 | 1.4718 | X45CrSi 9 3 | 401 S 45 | - | Z 45 CS 9 | F.3220 | SUH1 | X45CrSi8 | |

| - | 1.7321 | 20 MoCr 4 | - | 2625 | - | F.1523 | - | 30CrMo4 | |

| Stàilinn àrd neart tensile | A128 (A) | 1.3401 | G-X120 Mn 12 | BW10 | 2183 | Z 120 M 12 | F.8251 | SCMnH 1 | GX120Mn12 |

Comasan aFùirneis Tasgaidh Tasgaidh:

• Meud Max: 1,000 mm × 800 mm × 500 mm

• Raon Cuideam: 0,5 kg - 100 kg

• Comas bliadhnail: 2,000 tunna

• Stuthan Bond airson Togalach Shell: Silica Sol, Glainne Uisge agus am measgachadh.

• Tolerances: Air Iarrtas.

Buannachdan aCo-phàirtean tilgeadh tasgaidh:

- Crìoch uachdar sàr-mhath agus rèidh

- fulangas meud teann.

- Cumaidhean iom-fhillte agus toinnte le sùbailteachd dealbhaidh

- Comas ballachan tana a thilgeil mar sin pàirt tilgeadh nas aotroime

- Taghadh farsaing de mheatailtean tilgeadh agus aloidhean (iarann agus neo-iarannach)

- Chan eil feum air dreach ann an dealbhadh molltair.

- Lùghdaich an fheum air innealachadh àrd-sgoile.

- Ìosal sgudal stuthan.

| Stuthan airsonTasgaidh tasgaidhPròiseas aig Fùirneis RMC | |||

| Roinn-seòrsa | Ìre Sìona | Ìre na SA | Ìre na Gearmailt |

| Ferritic stàilinn | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Stàilinn Martensitic | 1Cr13, 2Cr13,3Cr13,4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Stàilinn Austenitic stainless | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404, 9. 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Sileadh cruadhachadh stàilinn gun staoin | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex stàilinn gun staoin | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| Stàilinn Àrd Mn | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Stàilinn inneal | Chr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Stàilinn a tha an aghaidh teas | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Alloy Nickle-bonn | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX (66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Aluminium Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Alloy copair | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800,C52100,C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Alloy cobalt-base | UMC50, 670, Ìre 31 | 2. 4778 | |

| LUCHD-OBRACHAIDH TAISGAIDH | |||

| òirlich | Millimeters | ||

| Tomhas | Fulangas | Tomhas | Fulangas |

| Suas gu 0.500 | ±.004" | Suas gu 12.0 | ± 0.10mm |

| 0.500 Gu 1.000” | ±.006" | Bho 12.0 gu 25.0 | ± 0.15mm |

| Bho 1.000 gu 1.500 ” | ±.008" | bho 25.0 gu 37.0 | ± 0.20mm |

| 1.500 Gu 2.000” | ±.010" | Bho 37.0 gu 50.0 | ± 0.25mm |

| Bho 2.000 gu 2.500 ” | ±.012" | Bho 50.0 gu 62.0 | ± 0.30mm |

| Bho 2.500 Gu 3.500 ” | ±.014" | Bho 62.0 gu 87.0 | ± 0.35mm |

| Bho 3.500 gu 5.000 ” | ±.017" | Bho 87.0 Gu 125.0 | ± 0.40mm |

| Bho 5.000 gu 7.500 ” | ±.020" | Bho 125.0 gu 190.0 | ± 0.50mm |

| Bho 7.500 gu 10.000 ” | ±.022" | Bho 190.0 gu 250.0 | ± 0.57mm |

| Bho 10.000 gu 12.500 " | ±.025" | Bho 250.0 gu 312.0 | ± 0.60mm |

| Bho 12.500 gu 15.000 | ±.028" | Bho 312.0 Gu 375.0 | ± 0.70mm |